Are you looking to ramp up your plastic parts production efficiency and save on costs? One of the key ways to achieve this in the world of manufacturing is by reducing injection molding cycle time. We'll guide you through the process and share some tried-and-true strategies to streamline your injection molding operations.

Before we jump into ways to reduce cycle time, let's first brush up on the basics of the injection molding process. From clamping to ejection, each stage plays a critical role in the overall efficiency of the process. By optimizing each step, you can significantly cut down on cycle time and increase productivity.

Implementing real-time monitoring systems allows you to stay on top of the injection molding process. By adjusting process parameters based on monitoring data, you can fine-tune settings for faster cycle times. This proactive approach to process control can lead to significant time savings in production.

Regular maintenance of molds and equipment is crucial for optimal performance. Keep an eye out for wear and tear that could impact cycle time. By addressing maintenance issues promptly and keeping your tools in top shape, you can ensure smooth operations and minimize downtime.

Looking for real-world examples of how reducing injection molding cycle time can benefit your business? Dive into some case studies that highlight successful implementations of cycle time reduction strategies. By learning from industry best practices, you can tailor your approach to fit your specific needs and see tangible results in your production efficiency.

However, the best way to reduce injection molding cycle time, to be honestly, find a professional plastic mold making supplier, we are just the correct one you are seeking for, please contact yoyo@hanking-mould.com, we will have expert engineers supprt you.

Check more of our case:

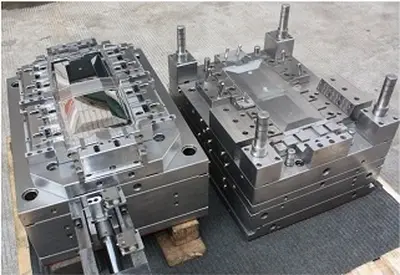

Injection Mold Design & Engineering

Plastic Mould Manufacturing Process

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China