There are many mold makers and plastic mould manufacturers in China, there are large-scale manufacturing plants, countless small factories and small works, and it is particularly difficult to find a mould supplier with good quality and reassurance if don't understand China's complex market. As a toolmaker, we are specializing in the design, manufacture and injection molding of plastic moulds for more than ten years. HanKing Mould is only 30 minutes drive from Shenzhen Baoan International Airport. It now covers an area of 2,000 square meters and has more than 50 employees.

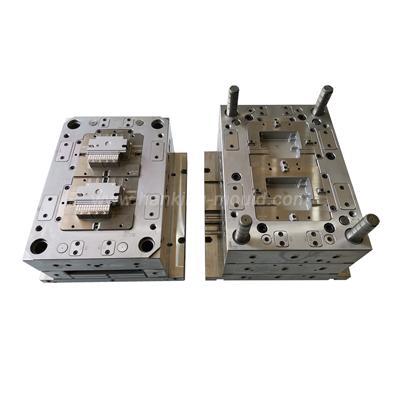

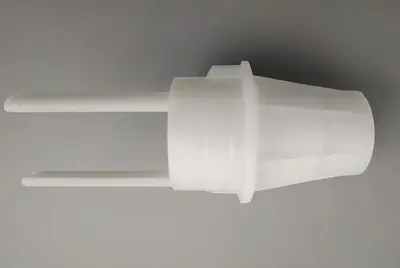

HanKing Mould is a professional plastic mould manufacturer with experience in plastic mould design and production in various industries such as medical, communications, automotive and electronics. Supporting equipment for mold processing, production and testing include FUNUC & YCM High-Speed CNC Machines, Sodick Wire-Cutting Machines & Sodick Mirror EDM Machine, Standy EDM Machines, ZISS CMM detectors, etc.;

In HanKing Mould, plastic moulds are made of imported steels from Germany, the United States, Sweden, etc. Each set of moulds provides the original material certificate of steels. Strictly control the error of the product from size to appearance;

HanKing Mould Engineering Ltd. implements strict quality control, material processing, final molding, quality inspection in each process, find problems in advance; Our project manager will work from design management, planning management, manufacturing and processing, logistics and transportation, shortening lead time, to maximize the benefits of customers.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China