Compared with American OEM manufacturers, the automotive mold makers all over Europe are providing the same auto mold at a faster speed, with higher quality and lower cost. The reason lies in laser heat treatment, which is close to the mainstream in Europe, but has almost never been applied in the United States.

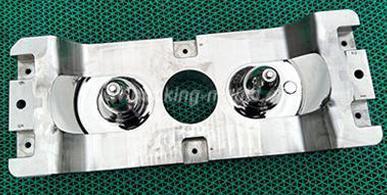

Laser heat treatment of automobile stamping mold on the side of fairing.

The application of laser heat treatment in Europe has been generally successful. It is inevitable that American OEM manufacturers adopt this technology. The barriers to laser heat treatment for American mold makers include the fact that the technology is still not well understood in the United States. Data on cost savings, quality, and schedule improvements in laser heat treatment have not yet been transferred to decision makers in the United States; and there are few reliable laser heat treatment workshops in the United States. However, it is clear that laser heat treatment is expected to be adopted rapidly in the US OEM industry.

What is laser heat treatment?

In the laser heat treatment process, the laser beam with typical spot size between 0.5 × 0.5 inch and 2 × 2 inch irradiates the surface of metal parts as a means of heat transfer. Laser energy is transmitted in such a way as to raise the temperature of the metal surface and heat affected zone (HAZ) above its metallurgical transition temperature. When the laser heat source is removed, the heat of the metal is removed by heat conduction to provide rapid quenching of the heating area, thus producing the required hardness. The operation details of the laser beam can be finely adjusted to precisely control all aspects of the hardening process. Depending on the geometry, laser heat treatment also allows for the processing of inaccessible areas by sight distance. Laser heat treatment is sometimes called laser hardening.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China