With the development of the market economy, the production of the automobile industry is getting faster and faster. Nowadays, the rapid development of the automobile industry has put forward higher and higher requirements for automobile lighting fixtures.

The quality of automobile lighting fixtures is very important to the automobile, such as the appearance should be integrated with the appearance of the whole car, it should be beautiful, easy to use, and in line with the regulations of fluid mechanics. Therefore, the technical design of the automobile lights is also accompanied by the development trend of the automobile industry.

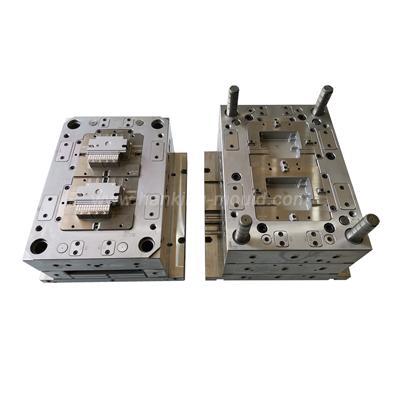

The material and process characteristics of injection mould of automobile lights

The automobile light is generally composed of a base and a light shade. The base is usually made of BMC, a thermosetting plastic raw material, while the light shade can be produced and processed from PMMA, PP, ABS and other raw material, and is generally with two or three colours. In the injection mould processing technology level of the two-colour automobile lights, especially should pay attention to the two-colour injection, the centre distance of two screws and the centre distance of the two-colour mould should be relatively consistent. It should also be noted that when the automobile lights injection mould is forming, multicolour injection moulding requires two basic compatibility conditions, which are adhesion compatibility and processing compatibility respectively.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China