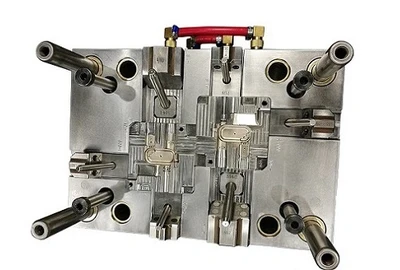

The structural form and processing quality of the injection molding mold directly affect the quality and production efficiency of plastic products. There are many failures in the production process of injection molding molds.

During the injection molding process, the gate sticks to the gate sleeve and is not easy to come out. When the injection molding mold is opened, the product is damaged by cracks. In addition, the operator must knock out the tip of the copper rod from the nozzle to loosen it before demoulding, which seriously affects the production efficiency. The main reason for this failure is the poor finish of the gate taper hole and the knife marks in the circumferential direction of the inner hole.

In addition, the material is too soft, the small end of the taper hole is deformed or damaged after a period of use, and the spherical arc of the nozzle is too small, causing the gate material to produce a rivet head here. The taper hole of the sprue sleeve is difficult to process, and standard parts should be used as much as possible. If you need to process it yourself, you should also make or buy a special reamer. The taper hole needs to be ground to Ra0.4 or less. In addition, gate pulling rods or gate ejection mechanisms must be provided.

The guide post mainly plays a guiding role in the injection molding mold to ensure that the molding surfaces of the core and the cavity do not touch each other under any circumstances, and the guide post cannot be used as a force-bearing part or a positioning part.

In the following cases, the movable and fixed molds will generate huge lateral deflection force during injection:

1) When the wall thickness of plastic parts is not uniform, the flow rate of the material passing through the thick wall is large, and a large pressure is generated here;

2) The side of the plastic part is asymmetric, such as the injection mold of the stepped parting surface, the back pressure on the opposite sides is not equal.

For large molds, due to the different filling rates in each direction and the influence of the mold's own weight when the mold is installed, the dynamic and fixed mold offsets occur. In these cases, the lateral deflection force will be applied to the guide post during injection, and the surface of the guide post will be rough and damaged when the mold is opened.

In order to solve the above problems, high-strength positioning keys are added on the parting surface of the injection molding mold, one on each of the four sides. The most convenient and effective way is to use a cylindrical key. The verticality of the guide hole and the parting surface is very important. In the processing, the movable and fixed die are aligned with the position and clamped, and then the boring machine is finished at one time, which can ensure the concentricity of the movable and fixed die holes and minimize the verticality error. In addition, the heat treatment hardness of the guide post and guide bush must meet the design requirements.

When the injection molding mold is injected, the molten plastic in the mold cavity generates a huge back pressure, generally 600~1000 kg/cm. Mold manufacturers sometimes do not pay attention to this problem, and often change the original design size, or replace the moving template with low-strength steel plates. In the mold with ejector ejector, due to the large span between the two sides, the template is bent during injection.

Therefore, the movable template must be made of high-quality steel with sufficient thickness, and low-strength steel plates such as A3 should not be used. When necessary, support columns or support blocks should be set under the movable template to reduce the thickness of the template and improve the bearing capacity.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China