Today, we're going to take a closer look at the hot stuff in the world of injection molds – hot runner systems. These systems play a crucial role in the injection molding process, and understanding their principles, design, and applications can make a world of difference in your projects.

If you're new to the world of injection molding, you might be wondering what hot runner systems are all about. Simply put, hot runner systems are a set of components that help to maintain a consistent temperature in the channels through which molten plastic flows in an injection mold. This, in turn, ensures that the plastic material is properly distributed and molded into the desired shape.

Understanding the principles, design, and applications of hot runner systems is essential for anyone working in the injection molding industry. These systems offer a range of benefits, from improved part quality to reduced cycle times, making them a valuable tool in the arsenal of any injection molder.

So, how do hot runner systems actually work? The key principle behind hot runner systems is heat management. By keeping the channels through which the plastic flows at a consistent temperature, hot runner systems help to prevent premature cooling and ensure that the material reaches every part of the mold cavity.

One of the main advantages of using hot runner systems is the reduction of material waste. Since the system helps to maintain a constant temperature in the channels, there is less chance of the plastic material solidifying prematurely, leading to better part quality and lower production costs.

When it comes to designing hot runner systems, there are several factors to consider. For starters, you'll need to choose the right type of system for your specific project. There are three main types of hot runner systems: open, valve gate, and insulated runner, each with its own set of benefits and challenges.

Other design considerations include material selection, gating, and temperature control. Selecting the right materials for your hot runner system is crucial, as different plastics have different temperature requirements. Additionally, proper gating design and temperature control are key to ensuring that the plastic material flows smoothly through the mold without any issues.

Hot runner systems are commonly used in a variety of industries and applications. From automotive parts to consumer products, these systems can be found in a wide range of injection molding projects. The benefits of using hot runner systems, such as improved part quality and reduced production costs, make them a popular choice for many manufacturers.

Case studies can provide valuable insights into the successful application of hot runner systems. By showcasing real-world examples of how these systems have been used to achieve specific goals, we can better understand their potential and the value they bring to the injection molding process.

So, you're ready to incorporate hot runner systems into your injection molding projects – what's next? It's important to follow some best practices to ensure that you get the most out of your hot runner system. Start by selecting the right system for your project, taking into account factors such as material requirements, mold design, and production goals.

Maintenance and troubleshooting are also important aspects of implementing hot runner systems. Regular maintenance can help to prevent issues and keep your system running smoothly, while troubleshooting strategies can help to quickly address any problems that may arise during production.

Optimizing the performance and efficiency of your hot runner system is key to maximizing your investment. By following best practices and staying informed on the latest advancements in hot runner technology, you can ensure that your injection molding projects are a success.

Well, folks, we've covered a lot of ground in our exploration of hot runner systems for injection molds. These systems may seem like a small detail, but they can have a big impact on the quality and efficiency of your injection molding projects. By understanding the principles, design considerations, and applications of hot runner systems – and following best practices for implementation – you can take your injection molding game to the next level.

So, next time you're working on an injection molding project, remember the hot stuff – hot runner systems are here to help you achieve great results!

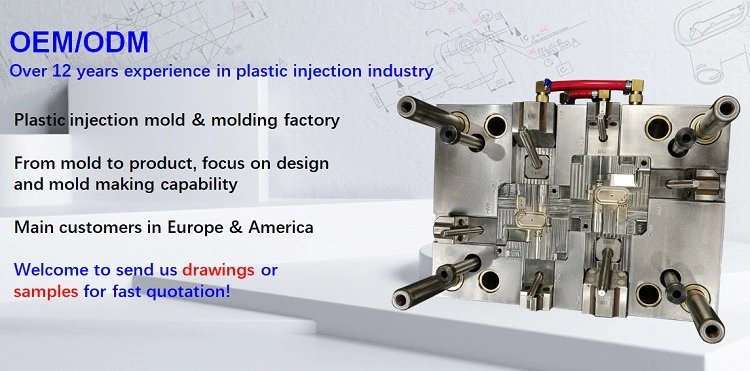

We specialize in plastic injection mould making service and plastic molding processes for 20 years, contact yoyo@hanking-mould.com for your plastic mould projects.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China