High-speed cutting is a relative concept. It is generally believed that the cutting speed of high-speed cutting is 5-10 times that of the ordinary cutting speed. There are also views that the spindle speed of the machine tool reaches 10000-20000r/min to belong to high-speed cutting.

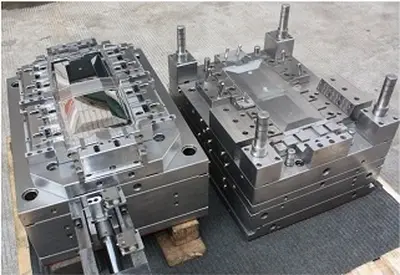

Precision mould adopts high-speed cutting processing technology, which can significantly improve processing efficiency and processing accuracy, reduce the cutting force, reduce the impact of cutting heat on the workpiece, and realize process intensification. It is an advanced processing technology with high efficiency and high quality.

At present, high-speed cutting technology has been widely used in precision mould manufacturing.

Except for the small moulds with particularly complex shapes and profiles containing narrow slits and deep grooves, which are still mainly processed by EDM, other moulds can be processed by high-speed cutting. Using high-speed cutting, the surface quality of precision moulds can reach the level of grinding, and the efficiency can be 3-6 times higher than that of EDM.

The basic principle of ultrasonic vibration grinding technology is: the high-frequency electrical oscillation signal (usually 16-25KHz) generated by the ultrasonic generator is converted into ultrasonic mechanical vibration by the ultrasonic transducer, and the ultrasonic vibration amplitude is amplified by the horn to drive the tool grinding wheel to generate vibration of the corresponding frequency so that periodic cutting is formed between the tool and the workpiece, that is, the tool grinding wheel performs high-frequency vibration while rotating and grinding.

By controlling the energy density of the electron beam and the energy injection time, different changes in the material can be achieved, and different processing purposes can be achieved, such as punching, cutting, photolithography and forming processing.

Electron beam processing of precision moulds is a processing technology that uses electric energy for high-speed processing such as perforation by focusing. If this train of thought is reversed, the electron beam is made into an extremely coarse shape without focusing, and after being enlarged, the extremely shallow (2 μm) layer on the surface is instantly melted by the reduced electric energy per unit area, and the irradiation time is only 2 μs.

Although the surface layer is melted instantaneously, the body part is still at a low temperature, so the melted part will be cooled down quickly. As a result, the surface will be amorphized, ie, amorphized. If this process is repeated along the entire surface, a very smooth mirror surface can be obtained, which is as smooth as the melted butter when solidified. Moreover, the formed amorphous surface is difficult to oxidize, that is, not easy to rust. This method may have gone beyond the scope of polishing and is an epoch-making processing technology.

The electro-jet machining process has the characteristics of good surface integrity and large aspect ratio and can process deep and small holes that are difficult to process by other processes, have complex structures, require high surface quality, and have no recast layer.

Electro-fluid machining is one of the high-pressure liquid beam small hole machining methods. It was originally a small hole processing method developed based on the metal tube electrode small hole processing method after comprehensively comparing the advantages and disadvantages of laser drilling, electron beam drilling and EDM small hole processing methods.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China