It has basically become a common product in our real life. In the process of actual use, this product will bring us better use guarantee. At present, most people want to know about what the structural components of automobile injection molding are in mould company. The following will give you a brief introduction.

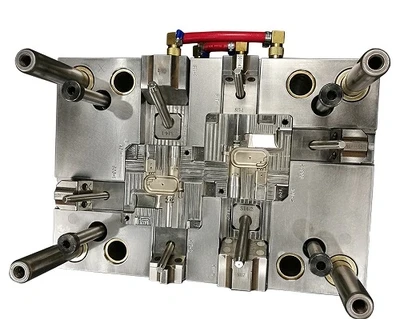

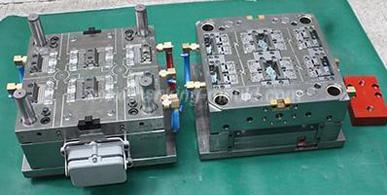

1. Molded parts of automobile plastic injection tooling

Molded parts can definitely be seen in automobile plastic injection tooling. These molded parts will have various materials, such as different material shapes or different material structures and material sizes. Generally speaking, these molded parts may vary a lot.

2. Pouring system of automobile plastic injection tooling

In the actual processing process of automobile plastic injection tooling, it has its own pouring system. This system can completely guide the molten plastic from the nozzle of the injection machine to the outer channel. Generally speaking, there are mainstream channels and shunting channels for pouring.

3. Guiding components of automobile plastic injection tooling

In the processing of automobile plastic injection tooling, in order to ensure that the original coating films and closed coating films can be accurately aligned with each wire component, the guiding component plays a decisive role in guiding.

4. Demoulding mechanism of automobile plastic injection tooling

In the process of setting up automobile plastic injection tooling, there are relatively many forms of device structures that can realize all parts structures. Generally speaking, these different copper film structures will be composed of various ejector fixing plates and some roofing plates, or various product materials such as related guide bushes.

5. Core pulling mechanism of automobile plastic injection tooling

During the processing of automobile mould plastic injection tooling, this core pulling mechanism will also be ejected for those parts with side openings or concave-convex parts during processing. Generally speaking, relevant tests must be carried out first. Because this lateral core pulling mechanism can separate the sliders, basically in this case, demoulding can be carried out smoothly.

6. Thermostatic adjustment system of automobile plastic injection tooling

In the process of actual work, automobile plastic injection tooling have to meet the different work needs of various places. In order to meet the requirements of the injection molding technology, they will have various adjustment systems, which can usually play a good role in the temperature adjustment of the mold, and can achieve great adjustment for a variety of different devices.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China