In modern industrial production, plastic mold products are widely used. In the design process of plastic molds, there are some fundamental considerations that cannot be ignored, and manufacturers of raw materials and plastic molds can be said to be important promoters of plastic mould design.

Since the target of product development or product improvement is to make the product perform well and at the same time achieve low production costs, the design mission of the injection mold manufacturer should include the selection of materials, the selection of processing methods, strength calculation and mold design, etc. The same is true in mold design.

As long as plastic die mold maker supplier comprehensively consider these factors and follow up systematically, they can produce high-quality, commercially-effective molds. It is necessary to pay attention to the fact that the practicality and cost efficiency of plastics are not fixed, and the designer must pay great attention to the correct solution for material selection and processing process.

Plastic die mould manufacturers have a great influence on the production cost of plastic parts, and each design determines the cost of production, manufacture and assembly of plastic molds for sale. Cost savings can be achieved in many ways only by taking full advantage of the characteristics of plastic raw materials.

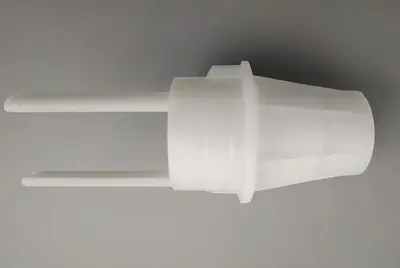

For the purpose of cost-saving, multi-functional integrated design, low-cost assembly skills, self-lubricating properties, and removal of surface treatment procedures can be taken into account in the design of plastic molds. Besides, it is necessary to pay attention to wall thickness, molds, technologies, materials, etc.

When designing plastic molds, plastic die mould manufacturers must not only carry out the design accounting of plastic products but also pay special attention to the gate design of the mold. It is necessary to select the correct gate system and the number and orientation of gates, as the type and orientation of gates will have a greater impact on the quality of the product.

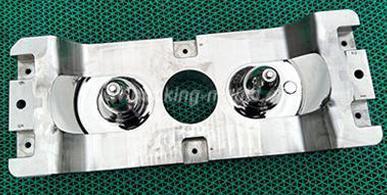

HANKING MOULD ENGINEERING LTD. designs and manufactures plastic injection molds in China, providing large factories for our global customers, and also provides injection molding production services, including secondary processing and assembly that customers need. Our global customers are from all over the world, such as the United States, Germany, Switzerland, France, Italy, Austria, Israel, etc.

Our business philosophy is "customer first, quality first". We are a trustworthy injection mold manufacturing company. If you have any needs, please feel free to consult us.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China