Introduction to Injection Molding and Tolerance

We're going on a journey to explore how things are made! Do you know that many parts of things we use every day are made by a process called injection molding? And there's something very important in making sure these pieces fit just right, called 'tolerance'. Let's find out what it means!

Understanding Tolerance in Molding

Tolerance is like a rule for how much a plastic part can be different from its perfect size. Imagine if you had a puzzle piece that was too big or too small - it wouldn't fit! Tolerance in molding helps make sure everything fits just right.

Why Tolerance is Important

If all the parts don't fit, our products or machines might not work. That's why knowing how much they can be different, but still okay, is super important.

Standards in Tolerance

Just like there are rules in games, there are rules for how much a part can be different. These rules help everyone make parts that fit together, even if they are made in different places.

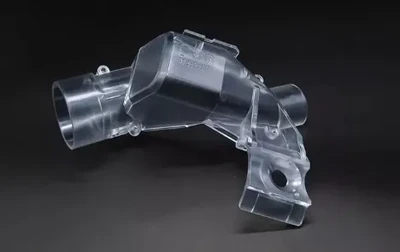

How Precise Can Injection Molding Be?

Precision is like hitting the bullseye in darts, and in molding, it's about making parts that are just right. Let's see how close to perfect the parts can be with this cool way of making things!

Minimum Precision in Molding

This is the most a part can be safely different from the target size to still fit as it should. It's like making sure your shoes aren't too tight or too loose.

Expecting the Best Fit

When we make things, we hope for them to be just right. We'll explore how often parts made by molding match up to what's expected.

The Math Behind Molding - Calculating Tolerances

Numbers can be cool when we use them to create awesome things! Let's dive into the world of math and figure out how we calculate the 'tolerance' for how heavy or light a part can be when it's made through injection molding.

Weight Tolerance in Parts

Just like when you have a bag of apples that might weigh a little more or less, plastic parts can also vary in weight. But we need to make sure they are not too heavy or too light. To do this, we use math to figure out the range within which the weight of a part can vary while still being considered acceptable.

Tolerance in Everyday Items

Think about the bottle caps on your favorite drinks or the parts in a car engine. These everyday items need to have just the right fit to work correctly. Tolerance ensures that the threads on a bottle cap match up perfectly with the bottle, and that all the components in a car engine fit together seamlessly.

Conclusion

We've learned a lot about how things fit together so well! Remember, tolerance in injection molding is all about making sure parts are just the right size and weight so everything works great together. We provide free parts analysis for your precision injection mould project, contact us immediately.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China