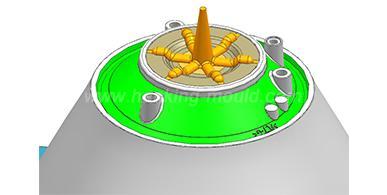

The mold refers to various molds and tools of the desired product, which are obtained by industrial injection molding, blow molding, extrusion, die casting or forging molding, smelting, stamping and other methods. In short, a mold is a tool used to make shaped items. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the product through the change of the physical state of the formed material. It is known as the "Mother of Industry".

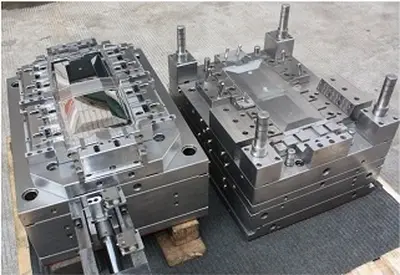

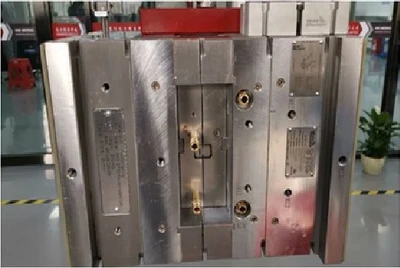

Before the formal opening of the mold, a set of prototype molds is often produced. Chinese manufacturer of prototype molds conducts a parameter test to verify the rationality of the number of cavities and the rationality of the cavity layout. At the same time, the defects of the design are exposed in the trial production, which is convenient to modify the design parameters when the mold is officially opened, so as to avoid that the processed mold cannot produce qualified products and cause huge losses. Especially for some molds with complex structure and high value, it is generally necessary to produce prototype molds first.

Compared with the formal mold, the prototype mold's Chinese producers need to be able to produce qualified products, and the cost needs to be much lower than the formal mold. The current approach is to use cheap materials when producing prototype molds, but the structure is not streamlined. Therefore, the cost during production is still relatively high, so now a prototype mold structure is needed to continue to reduce costs on the original basis.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China