Among the products of injection molds, large automobile moulds can be regarded as a relatively important type of products, because of their high value and relatively large volume, and the difficulty of production is much higher than that of ordinary products. Therefore, we suggest that if we want to produce such large-scale automobile moulds, we must pay attention to many aspects, especially in such places, we must be extra careful.

When producing such large-scale automobile moulds, we will see that many times, the selection of raw materials will be significantly different from some small molds, because both of them have a greater use environment and application requirements. The requirements of such large-scale automobile moulds are often more reflected in the strength of raw materials. Therefore, when selecting relevant plastic raw materials, it must also meet the corresponding attribute requirements, so as to ensure the production of large-scale automobiles. The mold can finally achieve the desired effect for us.

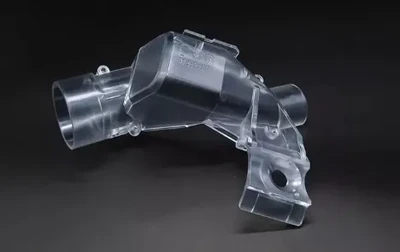

Generally, when large-scale automobile moulds are used, they are very particular about integrity. Once one of the details is damaged or has a problem, the entire mold can no longer be used. Therefore, when producing such molds, we must pay attention to every detail to ensure that the details will not be in place. The entire mold is scrapped.

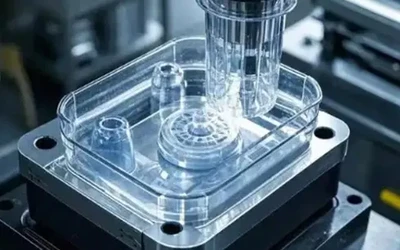

When producing auto molds, size and accuracy are basically a basis, and the same is true for such large auto molds. Its dimensional accuracy requirements will not be lower than those of small molds, and it is still necessary to pay attention to making The most accurate size can make this type of mold play a better role in the production line.

What we have shared above are some production requirements about the production of large-scale automobile moulds. After all, the value of large-scale automobile moulds is quite high, and the role they can play in the production process is also very critical. During production, if there is a problem with the mold, it will obviously cause trouble. Therefore, when producing this kind of automobile mould, we must pay attention to these key points to ensure that the final produced mold can meet the production requirements, which is able to bring reassuring quality.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China