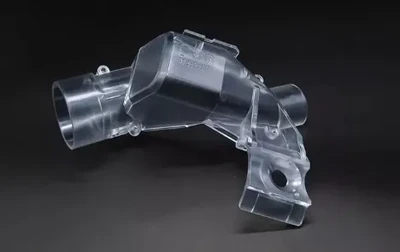

HASCO standard transparent High Polish Injection Mould for customer coffee grinder hopper and cover. It is transparent PCTG plastic resin which is food grade, very critical for appearance finishing, no sink mark and ejector on the surface.

High requirement for ejector system as well as the cooling system.

Individual cavity and core insert with Stavax S136 steel.

High glossy polished cavity and core side.

Part weight is nearly 270g.

Mould size 500*500*563 MM, the weight is over 1000 KG.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China